Scanning Concrete

Introduction

This presentation has been compiled and completed as a guide to the basic methodology employed by SlyCo Constructions for the scanning and subsequent coring of reinforced and post-tensioned slabs. It will briefly describe the machinery used as well as its limitations and tolerances and subsequent coring methodology.

Equipments

Radiodetection RD4000 Electro Magnetic Scanner

The Radiodetection RD4000 cable and pipe locator is widely seen as the industry standard, with the highest locate performance, multiple locate modes and ease of use for locating utilities, marking for construction, mapping or fault finding.

Highest performance digital Receiver even in the presence of interference

Fast, clear, positive response even in congested areas

Position and depth measurement

Current measurement to identify individual networks

Real Sound - audible perception of locating dynamics

Multiple modes - address the most demanding requirements

Ease of use - large clear display and positive keypad and control paddle

Highest sensitivity

Best Signal to Noise

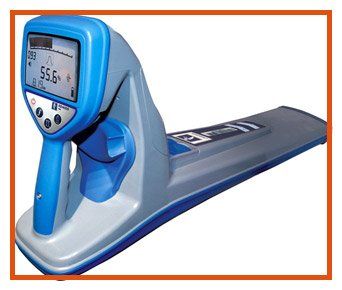

Hilti PS1000

The PS1000 X-Scan is designed to provide a real-time view of the inside of concrete structures and generates true images automatically, for direct on-site evaluation of scan data. It displays a top view of the scan for easy mapping of the objects detected plus cross sections in both directions for easy identification of multiple layers in concrete structures.

The PS1000 can be used for the inspection of floors, decks, slabs, balconies, etc. in structures such as tunnels, bridges and buildings and will locate rebar and tendons in structures at depths of up-to 400mm.

Provides a real-time inside view of concrete structures and generates true images automatically for direct on-site evaluation of scan data by the user - no expert skills required

Features three scan modes for specific applications: Quick-Scan detection, Quick-Scan recording and Image-Scan (2-D and 3-D data visualisation with top view and cross sectional views)

Compact all-in-one hand-held design offers easy, user-friendly operation, quick start-up for speed of use plus unmatched data visualisation

Displays a top view of the scan for easy object mapping plus cross sections in both directions for easy identification of multiple layers in concrete structures

Scanning & Coring Methodology

1. Survey and set-out the required area to be scanned and cored.

2. Test electrical scanner against known live power source.

3. Scan area for electrical cables

4. Scan area for reinforcing and post tensioning

5. Set out proposed cores with maximum space from detected reinforcing/PT/PowerNew Paragraph

6. Complete coring with experienced concrete cutter. Watch for signs of metal shavings and water loss, stop immediately if these are evident. Operator to core on 660V rated insulated mat

Limitations

Electrical Scanning – The electrical scan is only able to detect live power sources. SlyCo endeavour to have all known circuits live during the scanning to make detection possible. It is unable to detect empty conduits or circuits which are not energised. The device can also return a false positive with Post Tensioning in certain circumstances as these can sometimes carry a residual charge from the earthing of the buildings structure.

Reinforcing/Post Tension Scanning – This scanning is based on the Ground Penetrating Radar technology. Water and/or moisture is a major limitation of this device as it causes reflections of the waves and can prevent a clear image of the reinforcing below. Voids from toppings on void formers etc. also limit the device from penetrating the slab below. It is also noted that a high congestion of surface reinforcing will hide lower layers on items that are in close proximity and directly below other reinforcing. The best concrete scanning conditions are found over bare, smooth concrete where there is little to no moisture present.

Projects

Westfield Chermside – Completed over 6000 cores for column starters. No power cut and no post tensioning cut through.

AMP Pacific Fair

Westfield North Lakes

Team

Tony Sly – Director

Stephen Sly – Scanning Technician Lic Electrician 530786

Ryan Bruce – Scanning Technician

Various - Site Electrician

Conclusion

Scanning prior to coring is recommended as a risk reduction method. However, it should always be noted that there may be items that the scanners software or the technician completing the scan may not interpret correctly. For this reason, experienced concrete cutters should be utilised and always watch for metal filings and water loss to indicate reinforcing/PT or conduits that could contain cables. For the best effect when completing the scanning, any available documentation showing reo/PT layout should always be made available prior to scanning as well as any services drawing for the area made available to assist the technician with interpretation of the results.